What is Radio Frequency Welding?

Radio frequency (RF) welding is also called high frequency (HF) welding. This manufacturing process uses electromagnetic energy and pressure to weld and permanently bond thermoplastic, vinyl and coated fabrics to create a dimensional product. The RF sealing process is the most often referred to as radio frequency welding because of the way the electrostatic energy and pressure are used to realign the molecules to form a new, strong bond of the materials being fused together. Using this RF seal service, a new, one-piece permanent bond is created that is impenetrable and resistant to tearing.

How RF Welding Works

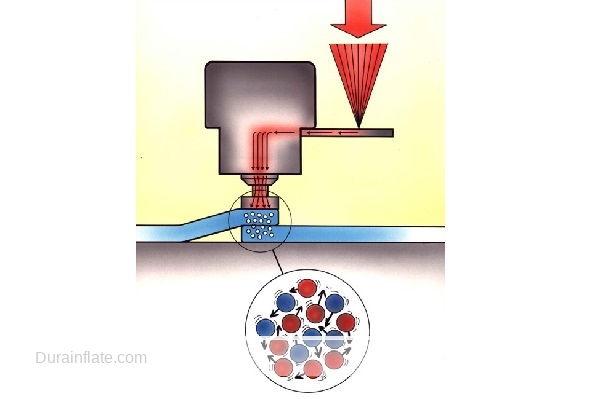

The radio frequency welding process scrambles the molecules in flexible polymeric materials to be joined for the dimensional requirements and product functionality. RF welding is a three-step process involving the preparation and positioning of the components, adding of electromagnetic energy and pressure to molecularly combine the materials, and finally, the cooling of the materials.

When cooled, the newly formed seam is as strong or even potentially stronger than the original material. The RF welding process can only be used with materials of a polar molecular construction, the most common being PVC and Polyurethane, although many other coated materials such as nylon are feasible. RF sealing works much better with stretchable unsupported film type materials such as TPU and TPE type materials.

RF welding is one the most reliable methods of sealing polymer materials for the fabrication of leak-proof, airtight inflatable products. Because of the attributes derived from a welded seam on pliable materials, the potential applications include everything from fluid bags for the medical industry to inflatable bladders for flotation devices. heat sealing are the preferred methods for the construction of most inflatable products as a result of the strong seal that is created when bonding the materials. They are used primarily in the industrial and medical industries because of the need for a durable air tight, leak-proof port and seam seal that allows for proper inflation and containment.

We can help customer determine the best process and material to use in the fabrication of inflatable product. Since every inflatable product serves a particular need or solves a problem, the inflation and containment process used is critical for the long-term success of the product.

Shapes

The materials to be welded are placed between the upper and lower tooling (electrodes) which are positioned between the machine bed on the bottom and the platen on the top. This is where the electromagnetic current is directed and the pressure is applied during the RF welding process. This radio frequency energy agitates and heats the materials causing them to melt together. The tooling die or working surface is where the shape of the product is created, as the electrodes simultaneously shape the weld to the tooling die, and the electromagnetic energy fuses the combination of materials to form the bond.

RF welding and tooling dies are used to make inflatable products in a variety of shapes and sizes.