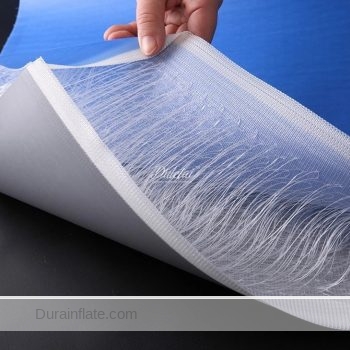

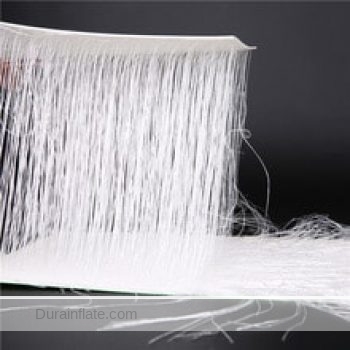

Drop stitch fabric

Drop stitch fabric construction is what allows an inflatable SUP to maintain its shape when it is inflated to high pressure. Without drop-stitch, the board would bulge out in the middle like an over-inflated air mattress. Using tens of thousands of tough polyester threads, drop stitch fabric lets us build inflatables with flat surfaces that can be inflated to rock-hard rigidity. You get hard-shell performance along with the easy transportation and storage of an inflatable. Drop stitch fabric SUP boards use the toughest drop-stitch materials in the industry. Sidewalls use two PVC layers specifically manufactured for superior air holding. Unlike typical PVC tarpaulin, the specialized sidewall material features internal fibers coated in liquid PVC before incorporation with the outer PVC layer, making the layers more durable and resilient than ever before.

DROP STITCH BASE FABRIC TYPES:

Warp knit (tricot) and woven base faric are all made from polyester DTY yarns but from different machines. Warp knit is the most widely used on the market due to the high production speed. Woven base fabric production speed is only 30% of warp-knitting but it is light weight and robust, so usually used for luxury products.

| Diagram | Technology | Space length | Feature |

|

Warp knit | 5-30cm | Most widly used |

|

Woven | 3-30cm | Light weight |

To view material technical data please click ITEM NO. link to DuraTarpaulin.com

DuraTarps is our pvc material manufacturing business. You can find the latest and full range of pvc material collections, knowledge and specifications.

PVC WARP-KNIT DROP STITCH FABRICS:

Warp knitted dropstitch is the most widly used. With ten thousands of high strength threads between top layer and bottom layer, this material is high performance of strength and suitable for all applications.

| Brand | Item NO. | Thickness | Weight | Applications |

|

DLT-6805 | 5cm | 2600gsm | Boat floor |

| DLT-6808 | 8cm | 2620gsm | Pool, Tub | |

| DLT-6810 | 10cm | 2650gsm | Gym mat | |

| DLT-6812 | 12cm | 2680gsm | Gym mat | |

| DLT-6815 |

15cm | 2700gsm | Paddle board | |

| DLT-6820 | 20cm | 2800gsm | Floating docks | |

| DLT-6830 | 30cm | 2850gsm | Floating docks |

PVC WOVEN DROP STITCH FABRICS:

Woven drop stitch is mainly used for luxury paddle boards and floating platforms. It offers reduced weight and increased tensile strength due to the way the internal fibres are woven.

| Brand | Item NO. | Thickness | Weight | Applications |

|

DLT-6812C | 12cm | 2200gsm | Gym mat, Floating docks |

| DLT-6815C |

15cm | 2200gsm | Paddle board |

TPU WOVEN DROP STITCH FABRICS:

TPU material is widly used for food and medical equipment. Drop-stitch fabrics with TPU film are designed for inflatable structures with high airtightness and ageing properties, along with minimum weight. This is a innovation of high-end material for dropstitch products.

| Brand | Item NO. | Thickness | Weight | Applications |

|

DLT-6805WTC | 5cm | 1025gsm | Boat floor |

| DLT-6805WT | 5cm | 1050gsm | Pool, Tub | |

| DLT-6812WT | 12cm | 1160gsm | Gym mat, Paddle board | |

| DLT-6815WT | 15cm | 1200gsm | Gym mat, Paddle board |

PVC WAVE STITCH DOUBLE WALL FABRICS:

In the year of 2022, we developed a new version of PVC dropstitch material called “Wave stitch“. With a unique internal weaving type, we created a light weight inflatable dropstitch material. This wave looking surface is ideal for outdoor camping mats and furnitures. And more, the other special feature is an easy-curve capability makes this material ideal for inflatable tubs and other products with a natural, smooth curving shape.

| Brand | Item NO. | Thickness | Weight | Applications |

|

DLT-6805V | 5cm | 1600gsm | Boat floor |

| DLT-6808V | 8cm | 1600gsm | Pool, Tub | |

| DLT-6810V | 10cm | 1600gsm | Pool, Tub,Gym mat | |

| DLT-6812V | 12cm | 1600gsm | Gym mat |

Showing all 5 results

-

MORE INFO

MORE INFODLT-6808V Wave stitch fabric

In the year of 2022, we developed a new version of PVC dropstitch material called “Wave stitch“. With a unique internal weaving type, we created a light weight inflatable dropstitch material. This wave looking surface is ideal for outdoor camping mats and furnitures.

-

MORE INFO

MORE INFOTPU drop stitch

Drop-stitch fabrics with TPU coating are designed for inflatable structures with high airtightness and ageing properties, along with minimum weight. They are used for performant products as inflatable floors, rescue air tracks, SUPs etc. Our range starts at 50mm height, feel free to contact us if you have specific request.

-

MORE INFO

MORE INFODouble layer drop stitch

For the paddle board market, there are 3 types of dropstitch material that is wildy used, single layer which is the most widly used for standard paddle boards, it is low cost and light weight. But for some professional players, some luxury brands developed double layer dropstitch to improve performance of the product