Description

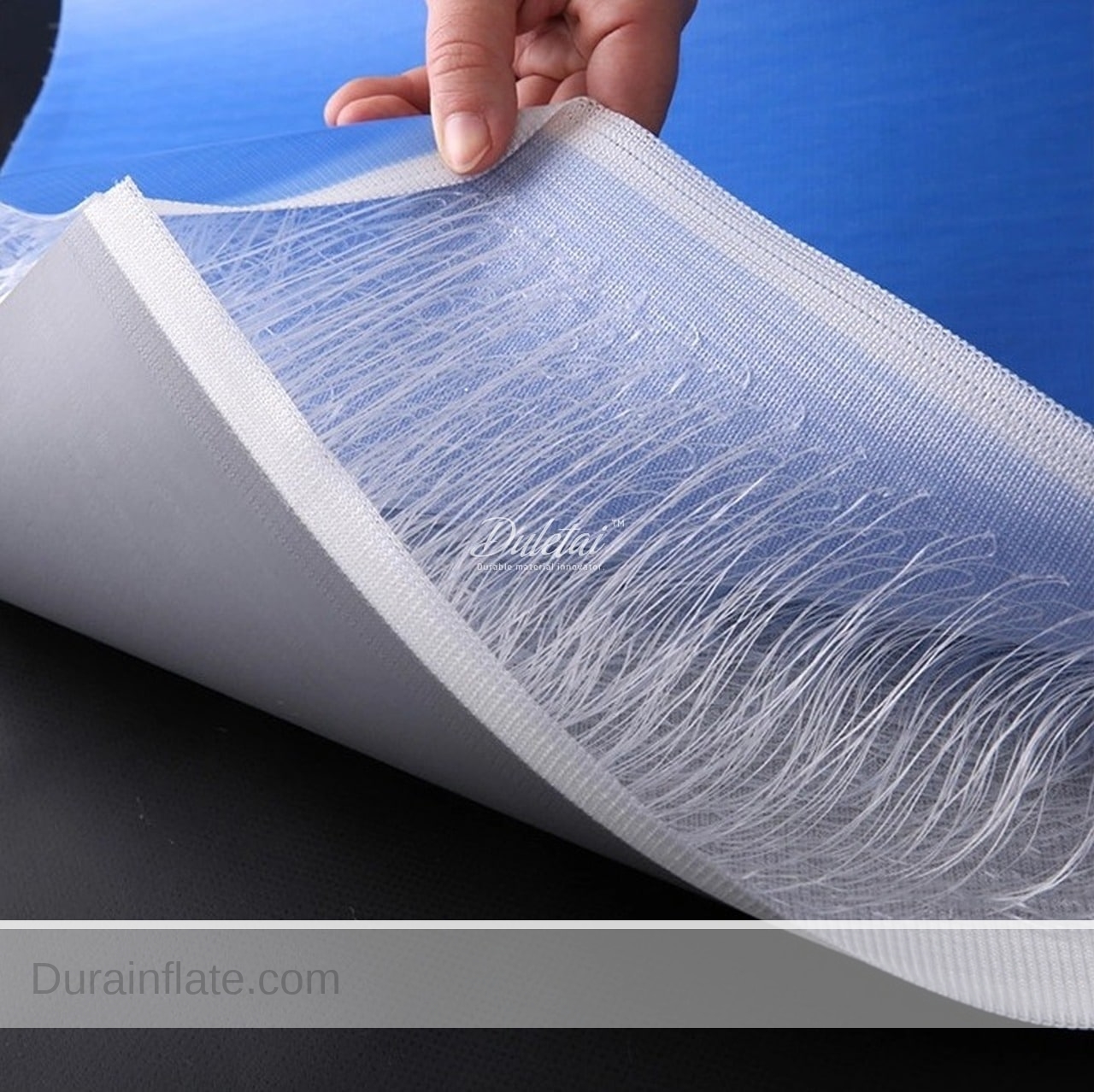

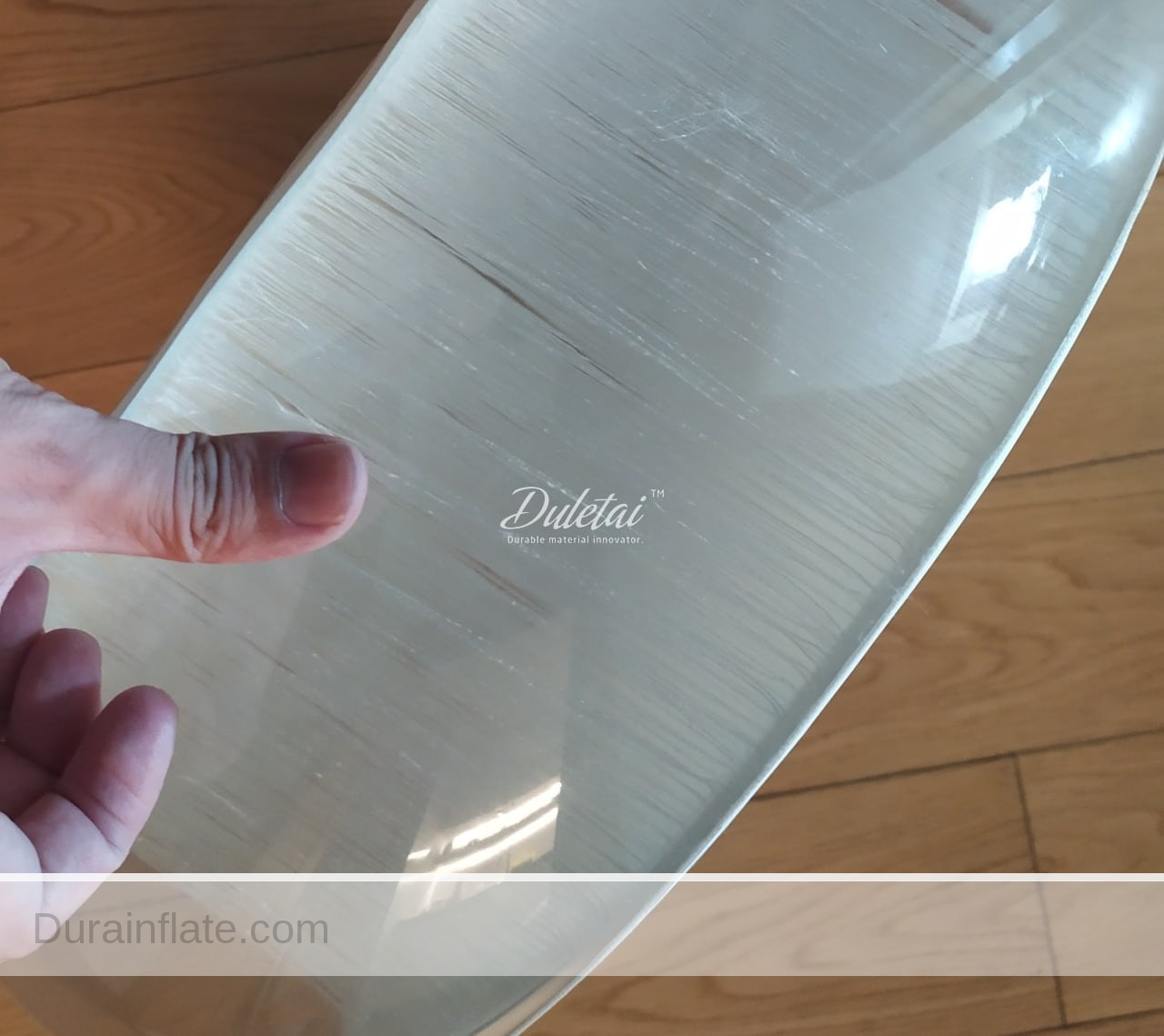

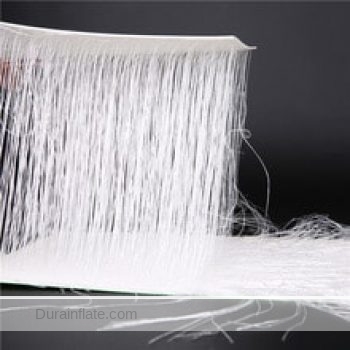

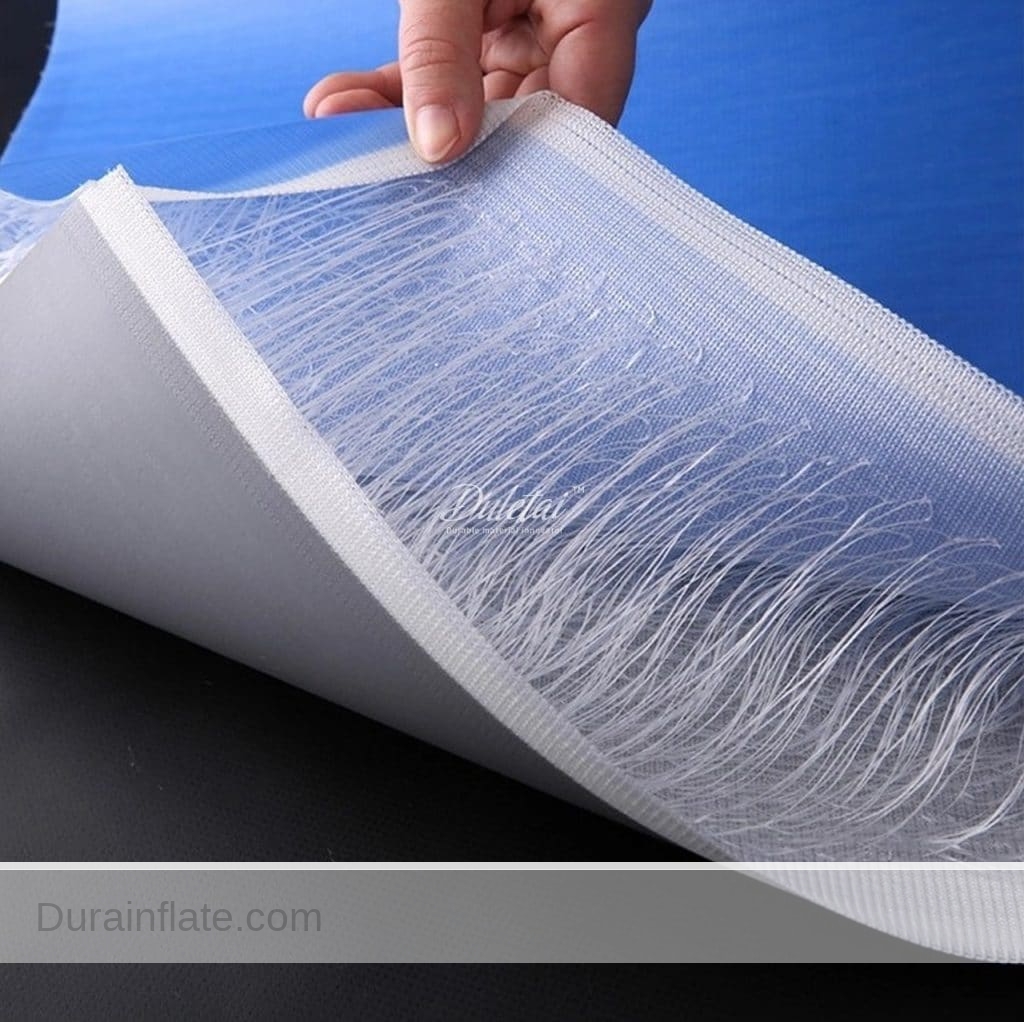

Double wall fabrics construction is a newly developed concept. The fabric surfaces are strongly connected to each other by the vertical pile fibers which are interwoven with the skins. Essentially it is tens of thousands of fine, evenly spaced polyester treads woven into the underside of the deck and base material ensuring that when the board is pumped up and the threads reach their maximum length, they don’t overinflate. Polyester is used throughout because it is strong, durable and has very little stretch. Therefore, this double wall fabrics can provide good skin-core debonding resistance, excellent durability and superior integrity. In addition, the interstitial space of the construction can be filled up with foams to provide synergistic support with vertical piles. Double wall fabrics are are widely used for Inflatable SUPs, boat bottom, Mattress, swimming pool, etc., featured by high strength, excellent quality stability and self-cleaning of surface, anti-aging and various weather resistance performance.

Raw material base fabric types:

Generally speaking, there are 2 type of base fabrics for dropstitch material

WARP-KNITTING VS WOVEN

Warp-knitting Dropstitch Material

Warp-knitting base fabric is the most widly used on the market that cover full range of inflatable products. This base fabric bounding structure is 1 thread on the end and 2 threads on the other end. The warp-knitting machine is low setup and running cost and high production speed, it means the lower cost for the raw material. The disadvantage is the material weight is higher.

Warp-knitting base fabric specification:

- Weight: 1000g

- After lamination weight: 2550gsm

- Thread: 1000X13000D

- Stable pressure: 15psi

There is increasing concerns from Europe and US regarding Phthalates. Phthalates refers to Phthalate Esters / PAEs, which are common addictive to soften plastics especially PVC in past 40 years and 80% of Phthalates are used in plastic products. It exists in others include inks, adhesives, sealant agents, paints, film coatings, glass fibers, leather, rainwear, footwear, dyestuff, perfume, softener, polish remover, lubricant, cosmetics and isolation for cables. Phthalates has toxic for reproduction. Based on the application and customer’s safety concerns, there are tests based on different Phthalates. The common testing are 3P, 6P, 7P, 15P and 16P. Our product has passed reach standard, and for higher requirement, we can make 6P. Which refers to 6 types of Phthalates below.

Standard: No more than 0.1% or 1000ppm

BBP – Benzylbutyl Phthalate

DIDP – Diisodecyl Phthalate

| Product | 5cm | 8cm | ||

| Pattern | Dot | Wave | ||

| Base Cloth | Polyester 500D( High tensile) | Polyester 500D( High tensile) | ||

| Space Length | cm | 5 (+/-5%) | 8 (+/-5%) | |

| Material Total Weight | g/sq.m | 2600 (+/-200) | 2620 (+/-200) | |

| Tensile Strength (2 layers) | N/5cm | 4100 x 2800 (+/-300) | 4100 x 2800 (+/-300) | |

| Adhesion Strength (2 layers) | N/5cm | 150 x 150 (+/-20) | 150 x 150 (+/-20) | |

| Pressure | Recommended | PSI(lbs/inch2) | 15 | 15 |

| Maximum | PSI(lbs/inch2) | 30 | 30 | |

| Standard width | Metre | 2.06 | 1.55/1.68 | |

| Surface | Matt | Matt | ||

| Length (standard) | Metre | 30,100,150,250 | 30,100,150,250 | |

| Product | 10cm | 12cm | ||

| Pattern | Dot ,In-line | Dot | ||

| Base Cloth | Polyester 500D( High tensile) | Polyester 500D( High tensile) | ||

| Space Length | cm | 10 (+/-5%) | 12 (+/-5%) | |

| Material Total Weight | g/sq.m | 2650 (+/-200) | 2680 (+/-200) | |

| Tensile Strength (2 layers) | N/5cm | 4100 x 2800 (+/-300) | 4100 x 2800 (+/-300) | |

| Adhesion Strength (2 layers) | N/5cm | 150 x 150 (+/-20) | 150 x 150 (+/-20) | |

| Pressure | Recommended | PSI(lbs/inch2) | 15 | 15 |

| Maximum | PSI(lbs/inch2) | 30 | 30 | |

| Standard Width | Metre | 1.68/1.85 | 1.68/1.85 | |

| Surface | Matt | Matt | ||

| Length (standard) | Metre | 30,100,150,250 | 30,100,150,250 | |

| Product | 15cm | 20cm | ||

| Pattern | Dot ,In-line | Dot | ||

| Base Cloth | Polyester 500D( High tensile) | Polyester 500D( High tensile) | ||

| Space Length | cm | 15 (+/-5%) | 20(+/-5%) | |

| Material Total Weight | g/sq.m | 2700 (+/-200) | 2800 (+/-200) | |

| Tensile Strength (2 layers) | N/5cm | 4100 x 2800 (+/-300) | 3600 x 4100 (+/-300) | |

| Adhesion Strength (2 layers) | N/5cm | 150 x 150 (+/-20) | 150 x 150 (+/-20) | |

| Pressure | Recommended | PSI(lbs/inch2) | 15 | 15 |

| Maximum | PSI(lbs/inch2) | 30 | 30 | |

| Standard Width | Metre | 1.68/1.85 | 2.00 | |

| Surface | Matt | Matt | ||

| Length (standard) | Metre | 30,100,150,250 | 30,100,150,250 | |

| Product | 30cm | ||

| Pattern | Dot | ||

| Base Cloth | Polyester 500D( High tensile) | ||

| Space Length | cm | 30(+/-5%) | |

| Material Total Weight | g/sq.m | 2850 (+/-200) | |

| Tensile Strength (2 layers) | N/5cm | 3600 x 4100 (+/-300) | |

| Adhesion Strength (2 layers) | N/5cm | 150 x 150 (+/-20) | |

| Pressure | Recommended | PSI(lbs/inch2) | 15 |

| Maximum | PSI(lbs/inch2) | 30 | |

| Standard Width | Metre | 2.00 | |

| Surface | Matt | ||

| Length (standard) | Metre | 30,100,150,250 | |

Woven Dropstitch Material

Woven base fabric is used for luxury inflatable products that require suprior stiffness and performance, it has only one thread from top to bottom connect 2 layers of base fabric. The base fabric woven machine cost is 4-5 times more than warp-knitting machine, and products speed is slower. The biggest advantage of woven base fabric is it’s weight is 30-40% lighter that warp-knitting.

Woven base fabric specification:

- Weight: 750g

- After lamination weight: 2000gsm

- Thread: 500D

- Stable pressure: 20psi

Double wall fabric applications:

- Water mat

- Air Track

- Runway Inflatable Drop-Stitch Watermat

- inflatable Docks

- Inflatable Dock Systems