One of the first things you must consider when deciding which inflatable boat to buy is the type of material it is made from.

Choosing the right kind of material is crucial as it will certainly impact your inflatable boat experience.

What materials are inflatable boats made of?

We are all aware that inflatable boats are made out of rubber. However, there are two particular kinds of rubber that are most widely used by inflatable water crafts manufacturers:

- Hypalon (a trademark for DuPont’s synthetic rubber)

- PVC (a synthetic plastic polymer)

Each material has its corresponding advantages and disadvantages, so before you decide which one to choose, it is best to review all of its properties first.

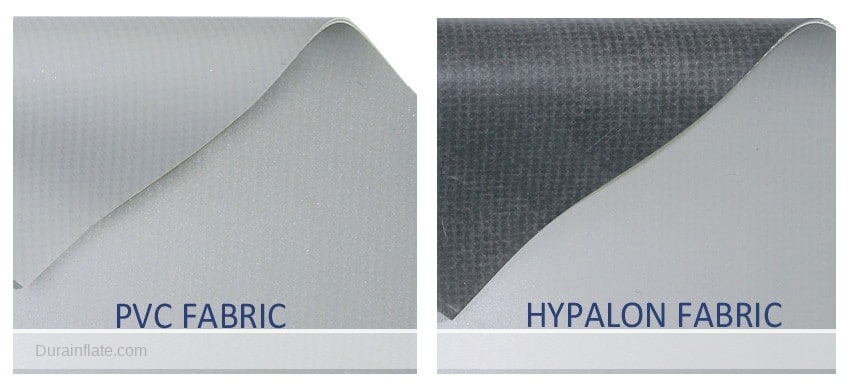

Hypalon fabric

Hypalon is a trademark for a series of chlorosulfonated polyethylene (CSPE) synthetic rubbers (CSM) made by DuPont Dow Elastomers.

It has many known applications in a range of industries due to its excellent air holding capabilities and outstanding resistance to the deteriorating effects of temperature extremes, ozone, oxygen, weather, oil, and chemicals.

Pros

- It has excellent resistance to abrasion and other mechanical abuse.

- It is unaffected by extreme temperatures and ultraviolet light, so it won’t harden even if left out in the sun.

- It is highly resistant to oil and a wide range of harsh chemicals which means spilling fuel or oil in it won’t be much of a deal.

- It doesn’t get brittle and deteriorate over time.

- Repairing it is rather easy as you can apply a patch while in the field.

Cons

- Since it is the most expensive coated material, inflatable boats made from Hypalon are priced much higher than boats made from PVC.

- It gets dirty more easily because of its porous finish.

- It is more labor intensive as it should be cold glued by hand.

- Its color fades when left out in the sun.

PVC fabric

PVC, or polyvinyl chloride, is a synthetic plastic polymer. It is known to be significantly less expensive than Hypalon. It has so many applications ranging from house siding, sewage pipes to furniture, toys, and of course, inflatable boats.

In preparing inflatable PVC boats for the water, chemicals such as plasticizers and stabilizers are added to the boat fabric. While these chemicals improve the boat’s performance, they are not environmentally friendly and they tend to leach out over time.

An inflatable boat made from PVC fabric is a good choice if you are looking for a less expensive boat. You just must keep in mind that inflatable PVC boats may not last as long as some of the higher priced ones.

Pros

- PVC is the most economical choice of material for inflatable boats.

- It makes a more lightweight and portable inflatable boat.

- Because it is a type of plastic, the seams of inflatable PVC boats can either be glued or thermobonded.

- It comes in a wider array of colors compared to Hypalon.

Cons

- When dry, PVC is not resistant to abrasion.

- Compared to Hypalon, it does not respond well to extreme temperatures.

- It is also not resistant to the deteriorating effects of chemicals, ultraviolet right,

- Inflatable PVC boats deteriorate over time, so they have shorter life cycle.

Proper care and Maintenance

If there is one important factor in determining the lifespan of an inflatable watercraft, regardless of the material it is made of, it is how it is cared for by the owner.

Listed below are some maintenance tips to keep in mind so you can use your inflatable boat for more years to come.

- You should clean your boat well every after use, especially when used in saltwater. You can use the same cleaning tools and materials for both PVC and Hypalon fabrics. However, you must be mindful of the right inflatable boat cleaners or tools to avoid damages.

Never use products such as bleach, ammonia, abrasive scouring pads and steel wool. Do take note also that soaps and detergents may leave residues that attract dirt and serve as food for mold and mildew.

- When storing, avoid leaving your boat out in direct sunlight.

- PVC fabric and the glue used to stick the PVC pieces together don’t respond well to heat, humidity and UV light. Make sure you store it in a well ventilated, dry place when folded up, not in a closed box.

- You also need to be mindful of how you fold the boat. It should be dry and clean before you store it. It also helps if you apply a coating of protectants before you fold it.

Which inflatable boat fabric best suits your needs?

Generally, PVC fabric won’t last as long as Hypalon fabric especially when exposed to prolonged periods of direct sunlight, especially when there are no protective measures taken such as a UV protectant.

Hypalon is highly preferable in hot climate areas. If you are planning to use your boat more frequently and keep it inflated most of the time, a Hypalon boat would be an excellent choice.

But if you’re after a lightweight and portable boat that can be easily rolled up and stored, then you may want to go for a PVC inflatable boat.

Consider the following before deciding which inflatable boat material is best for you:

- How will you use the boat? Will you be using it more often?

- In what water and weather conditions will you use the boat?

- Will the cost be an issue?

- Where will you store the boat? Will you be rolling it up and storing it more often?

Distinguishing PVC from Hypalon

If you are new to inflatable boats and are planning on buying a used boat, you may rightfully ask yourself: How can I tell PVC from Hypalon?

This is a very valid question, as many boat owners will not know the type of rubber their boat is made out of.

Here are a few ways you can tell whether the boat is manufactured out of Hypalon or PVC:

Inside color

Unscrew a large valve and look inside the tube with a light. You are trying to see the color of the inside of the tube.

With Hypalon, the color will be dark grey.

With PVC, the color will be the same as the outside of the tube, just a bit shinier.

Seams

A seam is where separate pieces of rubber are attached. The method of attaching PVC pieces is different from Hypalon.

PVC seams can be glued or heat welded, while Hypalon seams can only be glued.

If you see a heat welded seam, you know it is PVC. Most PVC boats have heat welded (thermo-bonded) seams, as they basically last forever.

Sand test

Lightly sand the tube with sandpaper, or something abrasive. PVC will show scratch marks, nothing else. Hypalon will produce dust and the color will become matt.

Summary: Hypalon vs. PVC

For us to compare Hypalon and PVC fabrics better, let’s take a closer look at the table shown below.

| HYPALON | PVC | |

|---|---|---|

| Resistant to extreme temperature | Yes. | Not as much. |

| Resistant to ultraviolet light | Yes. | Not as much. |

| Resistant to abrasion | Yes. | When dry, it is less abrasion resistant. |

| Durable | Yes. | Not as much. It gets brittle and deteriorates over time. |

| Economical | Not as much. It is the most expensive coated material. | Yes. It significantly costs less than Hypalon. |

| Lifespan | It lasts longer than PVC when exposed to prolonged periods of direct sunlight. | It won’t last as long as Hypalon especially when exposed to direct sunlight. |